AKYAPAK, presents extensive alternatives about big sized profile bending machines too.

Our machines are strong and reliable with their St-52 weld construction body. Minimum flexion causes less deformation, by the help of our machines' enlarged roll diameters. By the help of big measurements of bearings, durability and high bending momentum can be obtained. Hydraulic cylinders' power enables to bend the bigger parts without any difficulty. Practical and universal rollers creates the possibility of easiness about bending various kinds of profiles, and this feature gives the opportunity of being more powerful and firm.

Our Profile Bending Machines are 3 Rolls driven. This feature allows to have the possibility of making, the high capaticied bending processes, real. Secondly, our 3 Rolls Driven machine minimizes the slip of the materials during the bending process. The two bottom rolls are driven hydraulic and they can make their movements independent from each other. Therefore, in comparision with the machines which are driven from the top roll, our machines' features enhance the ability of operators and give the opportunity to make prebending process on both edges.

Side supporters can move towards three directions, to reduce the deformations and to facilitate bending processes, especially about angles and spirals.

There are private productions up to the customers' demands on Big Profile Bending Machines, in addition to standart production. For instance;

• The distance between the rolls can be lengthen due to increase the bending capability.

• Three rolls can be produced as driven by separate reducers and hydraulic motors. (Except APK 360)

• The movement of bottom rolls and the rotation movement can be done in the same time with some hydraulic arrangements.

• The bottom rolls', rotation's and side supporters' movements can be arranged according to each other.

• Placement of the hydraulic tank up to the customer' s demand.

• Assembling the control panel on the machine body.

• Bottom rolls' movements can be adjusted too slowly for sensitive bendings.

• The bending speed can be increased.

STANDART EQUIPMENTS

• Machine body is steel (St-52) construction.

• On APK 280 - 240 and APK 180 rolls are driven by hydraulic motor+planetry gearbox. On APK 360 rolls are driven via 3 seperat hydraulic motor. On APK 300 top and lower rolls are driven with two seperate planetry gearbox.

• Variable speed of rotation on APK180, 240, 280.

• Hardened rolls.

• Shafts made of special steel, hardened and grounded.

• On APK 360, APK 300, APK 280, APK 240 and APK 180 guide rolls are hydraulic adjustable.

• Horizontal working.

• Lower rolls hydraulic moveable up and down.

• Digital display for lower rolls.

• Separate and moveable control panel.

• Electrical and hydraulic protection against overloads.

• Manual lubrication

• 400 Volt / 50 hz

• Suitable for “CE”

SPECIAL EQUIPMENTS

• Special rolls for tubes, profiles and angles.

• Digital display for hydraulic guide rolls.

• Variable speed of rotation on APK 300, 360.

• Special tooling sysems for bending U-I-H profiles.

• Extended shafts. (APK-360 except)

• NC Playback Control System.

• CNC Graphic Control System.

• Digital Readout for profile position indication.

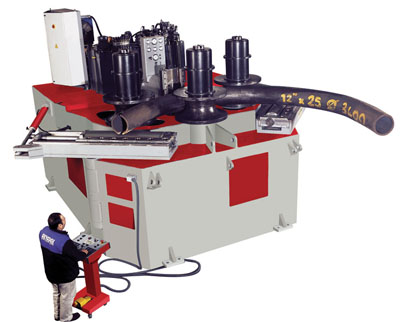

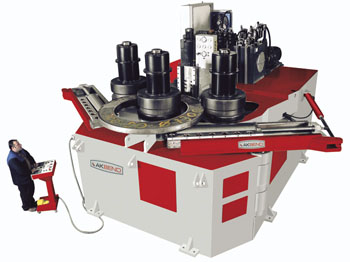

APK 360 S

APK 240

APK 180

APK 280

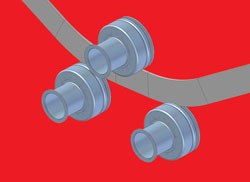

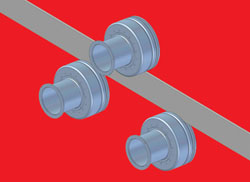

To bend U-I and H profiles without any damaging machine should be equipped with special pulling device.

|

![]()