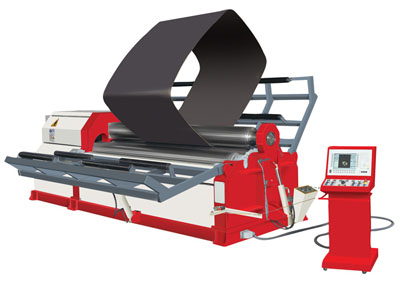

Akyapak manufactures 4 roller Hydraulic Plate Bending Machines with the capacity of bending from 2 mm to 100 mm in thickness and from 1000 mm to 6000 mm in width/ length.

Some of the features of Akyapak’s 4 roller Hydraulic Plate Bending machines are:

• Top roll and pinch roll hydraulically driven

• Up & down movements of the side rolls are hydraulically powered

• Drop-end controlling system to open and close from control panel

• Top roll tilts up

The frames of the machines are of fabricated, welded steel (St-52) construction. The roll shafts and the materials and bearings used in production are of good (European) quality. Also the torque limit of the machines is very high. NC playback and CNC graphic control systems are available as optional accessory.

Akyapak machines are designed using 3D CAD programmes and all calculations are carefully checked in the analyzing programme by experienced, specialist engineers before production is started. Machines are suitable for ’CE’ and all necessary electrical and hydraulic safety precautions are taken by Akyapak.

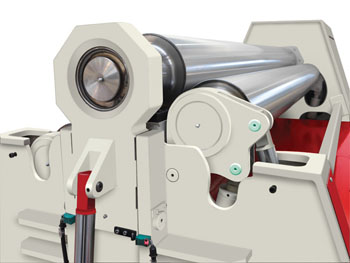

Spherical bearings are used for the rolls to minimize frictional resistance, which improves the capacity of the machines.

Optional accessories for easier bending are listed below:

• Cone bending device (standard)

• Induction hardened rolls (standard)

• Digital display for both side rollers (standard)

• Two speed control (standard)

• Infinitively variable speed of rotation

• Side and central supporters for big sheet metal diameters

• Material feed table

• CNC graphic and NC playback control system

• Cooling system

• Calibration

STANDART EQUIPMENTS

• Cone bending device.

• Induction hardened rolls.

• Digital display for both side rollers.

• Machine body is steel (St-52) construction.

• Two speed control.

• Separate control panel.

• All rollers mounted in bearing.

• Drop end controlled from control panel in order to release easily bent metal sheet and lifted upper rolls.

• Movement and parallelism adjustment of the rollers controlled from control panel.

• Center rolls are driven with hydraulic motor and planetry gear box.

• Electrical and hydraulic protection against overloads.

• Suitable for “CE”

SPECIAL EQUIPMENTS

• Infinitively variable speed of rotation.

• Side and central supporters for big sheet metal diameters.

• Material feed table.

• NC Playback Control System.

• CNC Graphic Control System.

• Changeable top roll with smaller diameters.

• Heat exchange.

• Calibration.

|

Out of feeding of the bent sheet is easy by the opening of hydraulic drop end. |

|

Since the swing guides are designed according to the levelarm principle, the machine provides more power to bend the material and by the help of this power, pre-bending is getting perfect and flat ends isdecreased to minimum level. |

|

Parallelism of the bottom and side rolls is achieved by stable steel torque which are connected to every roll. |

AHS 2100x25-30 mm NC

AH 3100x50-65 mm

AHS 3100x10-13 mm

AHS 3100x10-12 mm CNC

AHS 2100x30-50

AHS 3100x25-30

|

![]()